A former Fort Cavazos family received a $10.3 million award in economic and mental anguish…

The commercial construction industry in the United States is at a steady increase. According to the 2023 United States Construction Industry Report published by Research and Markets, the industrial construction industry will continue growing for the foreseeable future. The demand for commercial infrastructure will likely affect a marked increase in construction labor and associated industries, including heavy equipment manufacturing. One increasingly ambitious market is that of commercial cranes. Unfortunately, the need for rapid manufacturing and results has often rendered unsafe conditions with equipment defects that lead to crane accidents. Consequently, this reality will require workers and patrons in the construction industry to examine their equipment and practices to ensure overall safety and compliance with employee rights and government regulations. In this blog, we will discuss the common types and uses of commercial cranes, defects that can lead to injuries and what to do if you suffer a crane accident.

What are commercial cranes?

Cranes are heavy equipment designed to lift and move heavy objects. Cranes come in different shapes and sizes that can be used in various environments and have different applications. Some places where cranes are commonly used include residential and commercial construction, power generation, telecommunications, shipping and storage, and the oil and gas industry.

Main Components of Cranes

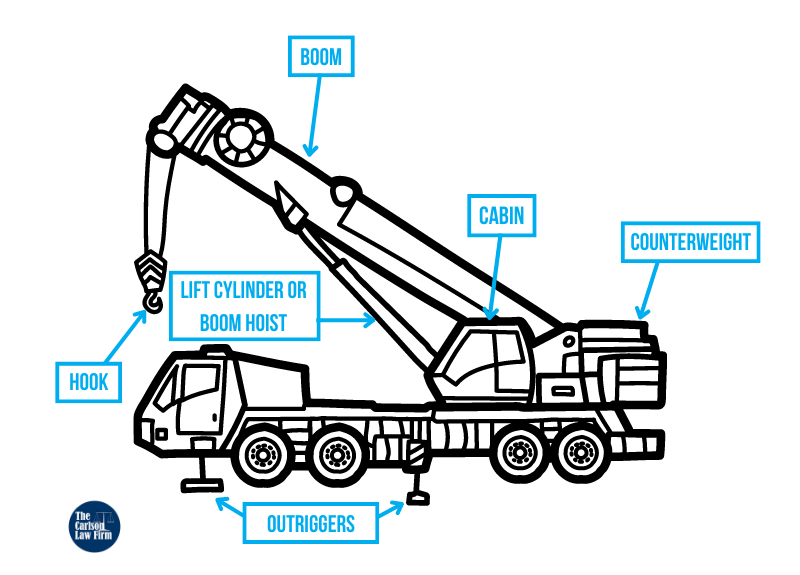

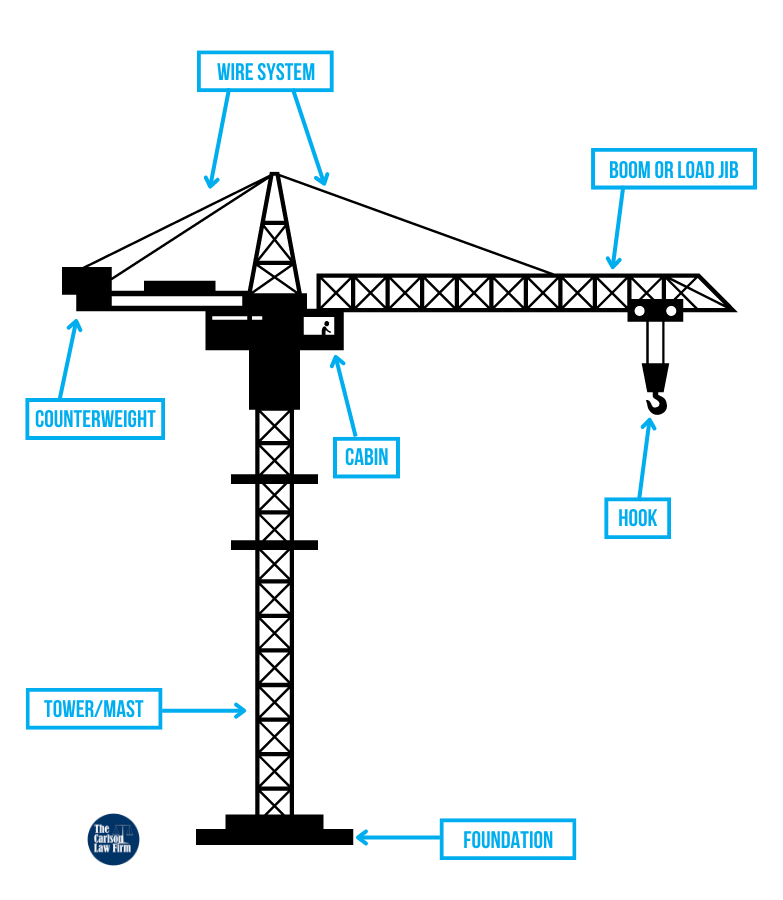

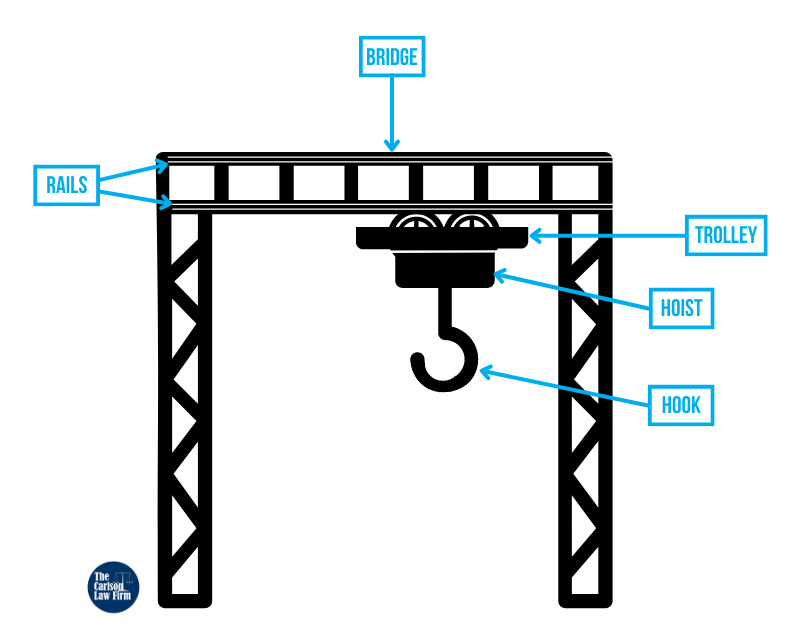

The main components of cranes can vary slightly depending on the type. The main components of the most common types of cranes are the boom, controls, hook, jib, outriggers and wire system/hoist.

- Booms: The boom is the crane’s long arm or lever. In fact, a crane boom is either fixed or telescopic. Telescopic booms can be extended or contracted to reach the needed height or length.

- Controls: The controls are handled by the crane operator, who uses them to direct the movement of the load. Moreover, some controls are located in an attached cabin or operated remotely to ensure the operator’s safety.

- Hooks: The hook component is located at the end of the hoist. It is used to secure the load. Hooks can be enhanced with a variety of approved attachments depending on the task at hand. Some common attachments are clamps, grab and lifting magnets.

- Jib: In tower cranes, the jib refers to the horizontal arm that carries the load. In other types of cranes, the term jib is used to describe a shorter extension of the boom that provides more height or reach.

- Outriggers: Outriggers are extensions in mobile cranes set on the ground to stabilize the crane.

- Wire System (Hoist): The hoist or wires use a pulley system to raise and lower the load.

Types of cranes. What are the most common uses of cranes in what industries?

Mobile Cranes

Mobile cranes are simple yet versatile machines that consist of a mobile platform with a mounted boom. This category of cranes includes several types of cranes such as vehicle-mounted cranes, floating cranes and crawler cranes.

Mobile cranes are the most commonly used type of crane because they are relatively easy to transport to different locations, compared to static or tower cranes. They can also be used for different applications. For example, mobile cranes are routinely used at construction sites, energy industry and land oil rigs. Unfortunately, they are also associated with the highest number of crane-related deaths and injuries. The U.S. Occupational Safety and Health Administration (OSHA) has established specific requirements and guidelines to ensure safety and minimize crane-related accidents.

Tower Cranes

Tower cranes are primarily used at large construction sites. As the name suggests, they have a very tall tower which is fixed to the ground or a stable platform. The horizontal lever arm is called a boom or load jib. It facilitates lifting and transporting heavy objects, thus rendering it significant importance in the construction industry.

Overhead Cranes (Bridge Cranes)

Overhead Cranes, also known as Bridge Cranes, are sturdy equipment in the form of a bridge used to move things horizontally across the rails on the bridge. The structure and functionality of overhead cranes can make them ideal for indoor manufacturing companies, automotive industries and some applications at construction sites. You can also find overhead cranes at ports being used to move heavy shipping containers.

Floating Cranes (Platform Cranes)

Offshore construction, drilling and transport often require moving massive loads. Floating cranes, also known as platform cranes or crane ships/barges, can move massive loads such as large ships. Currently, the world’s largest crane ship is the SSCV Thialf. The SSCV Thialf is 661.4 ft (0.2 km) long and 290 ft (ca. 88 m) wide. To put this into perspective, it can fit 2 American football fields. It is large enough to lift over 13227 US tons—that is approximately 24,000,000 pounds (ca. 10,886 t)!

Labor Statistics

The most recent report from the U.S. Department of Labor informs that crane and tower operators represent at least 45,210 of the nation’s employees. In 2018, Workforce Solutions estimated that crane and tower operating jobs in the Gulf Coast Region will grow 18% by 2028. The U.S. Bureau of Labor Statistics 2022 report shows that the top three states with the highest employment rates in crane operators are Texas, California and Florida. On the other hand, the states with the highest-paying crane jobs as of May 2022 are New York, Hawaii, Nevada, New Jersey and the District of Columbia. New York is the highest, with an annual mean wage of $136,330.00.

Operating a crane does not require extensive schooling, but it does have some basic qualifications. According to Workforce Solutions, most crane operators have a high school diploma or equivalent and receive on-the-job training through 3-5 year apprenticeship programs. Additionally, OSHA’s federal regulations require employers to certify their crane workers.

Crane Safety

Most crane accidents can be avoided by following OSHA requirements and safety measures. Crane operators and their employers can be proactive with regular, OSHA-compliant equipment inspections. Another important factor for crane operating sites is providing materials such as safety charts, checklists and periodic re-training or continued education. Although most cranes within each category have general similarities, operating different crane models can require specialized knowledge. Therefore, it is critical that crane workers adequately study the operating mechanisms and safety protocols before handling a new model.

OSHA Requirements

The Occupational Safety and Health Administration (OSHA) regulates crane-operating in the US. Crane operators handling equipment that exceeds 2,000 lbs must be certified by an accredited organization, such as the National Committee of Crane Operators, or qualified by an approved employer apprenticeship program. OSHA requires employers to enforce this rule and verify that crane operators demonstrate the appropriate technical knowledge and skills to perform their job safely.

Certification programs are designed to educate crane operators on the technical and practical aspects of crane operating. The tests include both written and practical components. While recertification is not mandatory, OSHA encourages employers to verify their operators’ continued technical and practicality over time.

Injuries and deaths

A study conducted by The Center for Construction Research and Training analyzed a sample of 632 crane accidents that resulted in the deaths of one or more construction workers. The study found that 78% of the deaths involved mobile or truck cranes, 12% involved overhead or gantry cranes, 5% involved tower cranes and 3% involved floating or barge cranes.

The study indicated that among the 632 crane accidents, the leading causes of deaths included the following:

- electrocution from overhead power lines;

- being struck by cranes crane loads, or crane parts;

- crane collapses;

- falls; and

- impingement between crane parts.

Crane Defects that Lead to Most Injuries

Wire Defects

Wires are an essential component of crane systems. Consequently, defective wires can be catastrophic. Wire defects can go unnoticed if not appropriately inspected before use. Therefore, it is important to follow inspection procedures to spot defects such as inclusions, inconsistent wire structure and improper construction.

Sheaves

The crane’s wires run through wheel-like parts called sheaves that direct the wire and amplify the lifting force. When sheaves are defective, it can cause the crane to fail. Some examples of defects are subpar pressure or tension capacity and materials that have increased friction.

Defective Operator Safety Mechanisms

Manufacturing companies have the responsibility of producing safe equipment. Developing machines with the proper safeguards to prevent injury is vital. For example, mobile crane designs should allow workers to operate the equipment away from potential hazards.

One unfortunate crane accident in 2018 resulted in the operator’s death when the outriggers pinched him. The operator was preparing to use the crane and deployed the outriggers to stabilize the mobile crane. As the outriggers were in movement, he was pinned between the vehicle component of the crane and the outriggers. The victim suffered fatal injuries from the extreme pressure of the. If the crane’s designers put the controls entirely out of the reach of the outriggers, they could’ve prevented his death.

Slew Bearings

The balance of a crane largely depends on its slew bearings. Slew bearings, also known as swing bearings, carry the weight of the superstructure and distribute it to the mount while allowing the crane to rotate. Due to the tremendous amount of pressure withstood by slew bearings, it is crucial that they follow adequate specifications. Different cranes will require slew bearings with different specifications based on the cranes’ rotational speeds, type of movements, capacity and environment. Using swing bearings with improper specifications ultimately causes the crane to topple over. This could potentially result in serious injuries to personnel and even bystanders, not to mention significant financial losses.

Recalls

Heavy equipment means companies should have a heavy burden of testing machinery to ensure quality and safety. OSHA has specific requirements that consider the rated capacity of the cranes. Note that each type of crane must pass tests that measure if they can withstand the load and applications specified for that model. As with most products, defects may become apparent when they’re already on the market. The manufacturers must notify all purchasers of the defective model or part of the safety hazard. Furthermore, if a company discovers a safety hazard and fails to inform the public adequately, they could be liable for any injuries that result from the defective crane.

What Do You Do After A Crane Accident?

Suffering injuries from a crane accident? Here are some critical next steps to consider:

- Get medical attention. If you are unsure if you are able safely seek medical attention without the help of emergency assistance, don’t risk it—call 911!

- Notify your employer. If the situation allows, notify your employer immediately and complete a report. If your injuries prevent you from notifying your employer immediately, do so as soon as possible or have a trusted, loved one help you get the message to your job. However, avoid volunteering information that could give the impression you are at fault for the accident.

- Contact a personal injury attorney with experience in crane accidents.

- Collect evidence. Rely on your attorney’s guidance to collect the right information such as medical records, photos of injuries and incident site as well as official incident reports

- Continue seeking medical attention. Above all else, you should take care of your health. On the other hand, it is also important to note that delaying or discontinuing medical care for crane-induced injuries and complicate your case. In other words, it can become more difficult to prove you have considerable injuries or that the crane’s failure caused them can become more difficult.

Crane Accident Attorneys

Most incidents related to crane failure happen at the workplace and can be devastating. Losing your capacity for livelihood at the very place you go to make a living can leave you with a sense of uncertainty and betrayal. Nevertheless, guidance from an attorney with experience in crane injury cases can pave the way to financial recovery. With the right attorney, you can seek compensation for your pain and suffering and your loss of income. Our Workplace Injury attorneys count on years of experience and the involved spirit needed to obtain fair results. If you or a loved one has suffered injuries from a crane accident, please call the Carlson Law Firm to learn how we can help you. We care. We can help.