We Apologize For the Inconvenience

The Blog Post That You Are Looking For No Longer Exists

Latest Blog Posts

Baylor Law Trial Professor Joins Carlson Law Firm as Of Counsel

April 25, 2024

KILLEEN, Texas — The Carlson Law Firm is proud to announce that distinguished trial attorney and Baylor Law School professor…

Carlson Cares Movie Night in Baytown: A Celebration of Family Books & Movies Under the Stars

April 25, 2024

BAYTOWN, TX – The Carlson Law Firm is delighted to invite the community to join us for a fun night…

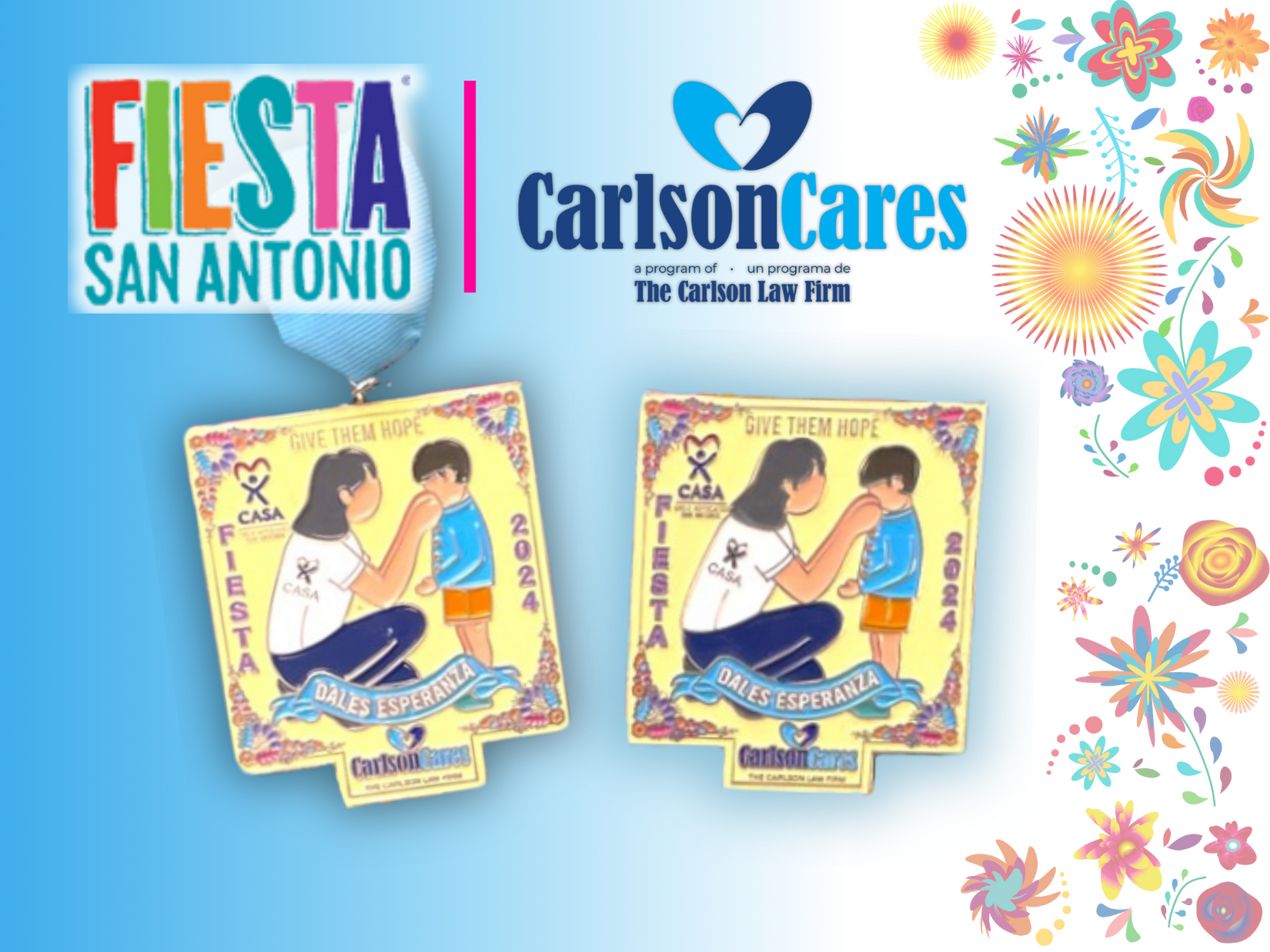

Carlson Law Firm Supports CASA at Pin Pandemonium 2024

April 18, 2024

[SAN ANTONIO] For the second consecutive year, The Carlson Law Firm will be sponsoring CASA at FIESTA San Antonio’s Pin…

What Unintentional Driving Habits Make Roads Less Safe?

April 10, 2024

Because of the number of times you’ve gotten behind the wheel of a car and survived, it is easy to…

Five Tips to Avoid Injury from April Fools Pranks

March 28, 2024

April Fool's Day is a time of laughter, pranks, and good-natured mischief. However, as a prestigious personal injury law firm,…

First Annual Día del Niño Celebration Offers Fun for the Kids and Bad Bunny for the Adults

March 27, 2024

[Killeen, TX] — Hip, hip, hooray! It’s almost time for Kids’ Day! Carlson Cares invites families from Killeen and surrounding…